Hot Water Driven Absorption Chillers

Horizontal Fire Tube Boilers

Thermal Oil Heaters

Exhaust Gas Boiler (EGB)

Steam Driven Absorption Chiller

Direct Fired Absorption Chiller

Exhaust Gas Absorption Chiller

Multi Energy Absorption Chiller

Water Cooled Compression Chiller

Air Cooled Compression Chiller

End Suction Pumps

Vertical Multistage Pumps

Borewell Pumps

Water Boosting System

Submersible Pumps

Electromagnetic Flow Meters

Turbine Flow Meters

Mass Flow Meters

Open Channel Flow Meters

Ultrasonic Flow Meters

Bellows Sealed Valve

Ball Float Trap

Thermodynamic Trap

Garments / Iron Trap

Thermostatic Air Vent

Vacuum Breaker

Sight Glass

Pneumatic Control Valve

Pressure Reducing Valve

Moisture Separator

Strainers

Non Return Valve

Automatic Pump Trap

Condensate Transfer Pumps

Rectangular Cooling Tower

Round Cooling Towers

Gasketed Plate Heat Exchanger

Brazed Plate Heat Exchanger

Water Softener Systems

Reverse Osmosis (RO) Plants

Ultra Filtration (UF) System

Vertical Water Tube Boilers

Coal / Biomass Boiler

Electric Steam Boilers

Diaphragms

Diaphragm Top Assembly

Diaphragms Valves

Vacuum Pumps

Vacuum Pump Kit

Manometer (Absolute Vacuum)

Vacuum Pressure Transmitter

DP (Differential Pressure) Switch

Flow Switch

Vacuum Pump Oil

Octoplus

Corrosion Inhibitor

Lithium Bromide Solution

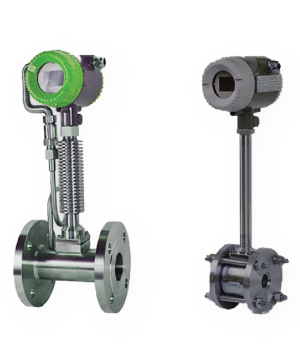

Vortex Flow Meters

Basic Information

Size: DN15 ~ DN300

Installation

Medium: Gas, Liquid, Steam

Medium

Temperature: - 40 to 450oC

Pressure

Rating: 1.6 Mpa

Accuracy: ± 1%

Protection

level: Sensor

IP65\IP68

Output

type: Pulse,

4-20mA, RS485

Power

supply: Sensor:

+12V DC, +24V DC; Transmitter: +12V DC, +24V DC; battery-powered

The vortex flow meter is widely used in industries such as textile, petroleum,

chemical, metallurgy, thermal, textile, and paper for measuring and controlling

superheated steam, saturated steam, compressed air, general gases (oxygen,

nitrogen, hydrogen, natural gas, etc.), and liquids (such as water, gasoline,

alcohol, benzene, etc.).

- Simple and sturdy structure with no moving parts, ensuring high

reliability and long-term operation.

- Easy installation and convenient maintenance.

- The detection sensor does not directly contact the measured medium,

ensuring stable performance and a long service life.

- The output is a pulse signal proportional to the flow rate, with no

zero drift and high accuracy.

- Wide measuring range with a ratio of up to 1:10.

- The pressure loss is minimal, operating costs are low, and it is more

energy-efficient.

- Within a specific Reynolds number range, the output signal frequency is unaffected by fluid properties, and the meter coefficient depends only on the vortex generator's shape and size.

- Applicable to a wide range of steam, gas, and liquid flow measurements.

Unsupported file type.