Hot Water Driven Absorption Chillers

Horizontal Fire Tube Boilers

Exhaust Gas Boiler (EGB)

Steam Driven Absorption Chiller

Direct Fired Absorption Chiller

Exhaust Gas Absorption Chiller

Multi Energy Absorption Chiller

Water Cooled Compression Chiller

Air Cooled Compression Chiller

End Suction Pumps

Vertical Multistage Pumps

Borewell Pumps

Water Boosting System

Submersible Pumps

Electromagnetic Flow Meters

Vortex Flow Meters

Turbine Flow Meters

Mass Flow Meters

Open Channel Flow Meters

Ultrasonic Flow Meters

Bellows Sealed Valve

Ball Float Trap

Thermodynamic Trap

Garments / Iron Trap

Thermostatic Air Vent

Vacuum Breaker

Sight Glass

Pneumatic Control Valve

Pressure Reducing Valve

Moisture Separator

Strainers

Non Return Valve

Automatic Pump Trap

Condensate Transfer Pumps

Rectangular Cooling Tower

Round Cooling Towers

Gasketed Plate Heat Exchanger

Brazed Plate Heat Exchanger

Water Softener Systems

Reverse Osmosis (RO) Plants

Ultra Filtration (UF) System

Vertical Water Tube Boilers

Coal / Biomass Boiler

Electric Steam Boilers

Diaphragms

Diaphragm Top Assembly

Diaphragms Valves

Vacuum Pumps

Vacuum Pump Kit

Manometer (Absolute Vacuum)

Vacuum Pressure Transmitter

DP (Differential Pressure) Switch

Flow Switch

Vacuum Pump Oil

Octoplus

Corrosion Inhibitor

Lithium Bromide Solution

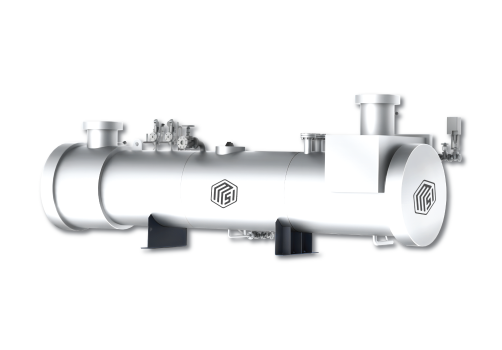

Thermal Oil Heaters

Basic Information

Steam Capacity: 0.4 to 10 Mkcal/h

Efficiency: 98%

Design Pressure: Upto 10 barg

Fuel Firing Options: Natural Gas, LPG, Biogas, Diesel, Furnace Oil, Dual Fuel, Tri Fuel

Thermal oil boiler is an indirect heating system in which a liquid

phase heat transfer medium is heated and circulated to one or more heat energy

users within a closed-loop system. It has cylindrical coils through which the

recirculation fluid passes. The burner fires into the centre of the coil

system, heating the liquid. Typically, the fluid temperature rises between 200C

to 400C between the heater inlet and outlet.

- Triple Pass energy efficient design ensures lowest operating costs.

- Integrated design, minimum footprint, and easiest installation.

- VFD drive burner blower fan, ensure ultimate fuel burnout rate 99.9%, save fuel costs.

- VFD Control oil circulation pump, ensures energy saving.

- High Output range from 0.4 to 10 Mkcal/h and design pressure up to 10 bar.

- Adaptable design for use with various types of fuel and as a multi-fuel

firing unit.

Unsupported file type.