Horizontal Fire Tube Boilers

Thermal Oil Heaters

Exhaust Gas Boiler (EGB)

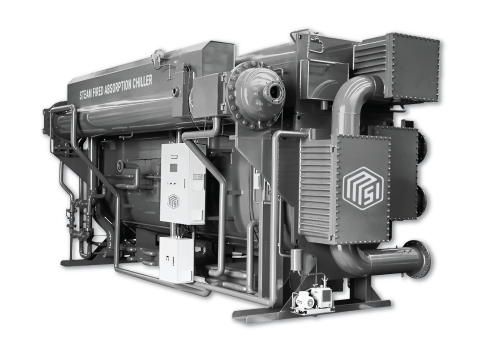

Steam Driven Absorption Chiller

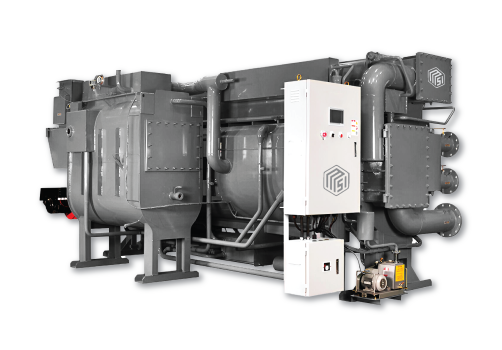

Direct Fired Absorption Chiller

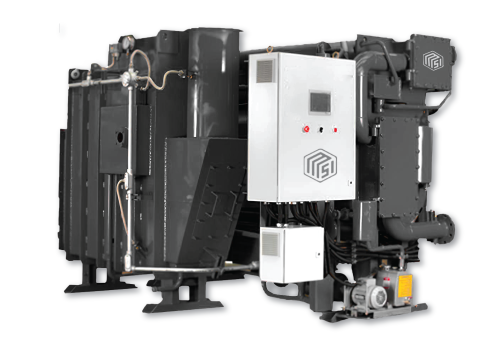

Exhaust Gas Absorption Chiller

Multi Energy Absorption Chiller

Water Cooled Compression Chiller

Air Cooled Compression Chiller

End Suction Pumps

Vertical Multistage Pumps

Borewell Pumps

Water Boosting System

Submersible Pumps

Electromagnetic Flow Meters

Vortex Flow Meters

Turbine Flow Meters

Mass Flow Meters

Open Channel Flow Meters

Ultrasonic Flow Meters

Bellows Sealed Valve

Ball Float Trap

Thermodynamic Trap

Garments / Iron Trap

Thermostatic Air Vent

Vacuum Breaker

Sight Glass

Pneumatic Control Valve

Pressure Reducing Valve

Moisture Separator

Strainers

Non Return Valve

Automatic Pump Trap

Condensate Transfer Pumps

Rectangular Cooling Tower

Round Cooling Towers

Gasketed Plate Heat Exchanger

Brazed Plate Heat Exchanger

Water Softener Systems

Reverse Osmosis (RO) Plants

Ultra Filtration (UF) System

Vertical Water Tube Boilers

Coal / Biomass Boiler

Electric Steam Boilers

Diaphragms

Diaphragm Top Assembly

Diaphragms Valves

Vacuum Pumps

Vacuum Pump Kit

Manometer (Absolute Vacuum)

Vacuum Pressure Transmitter

DP (Differential Pressure) Switch

Flow Switch

Vacuum Pump Oil

Octoplus

Corrosion Inhibitor

Lithium Bromide Solution

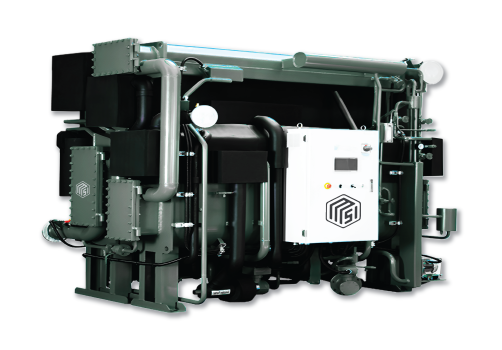

Hot Water Driven Absorption Chillers

Basic Information

Capacity: 30 ~ 2000RT (105 ~ 7033kW)

Input Energy: Hot Water

Hot Water Temp: 80 ~ 120℃

Hot Water Absorption Chiller is a thermally driven cooling system that uses hot water as an energy source instead of electricity. It operates based on the absorption refrigeration cycle, utilizing lithium bromide (LiBr) and water as the working pair. Water acts as the refrigerant, while lithium bromide serves as the absorbent. These chillers are commonly used in industrial and commercial cooling, as well as cogeneration systems, where a low-temperature hot water source is available. The system is a cost-effective and sustainable cooling solution.

- Greater ΔT for hot water inlet and outlet.

- Achieving a COP of 0.825 ensures ultimate performance.

- Lowest footprint and power consumption.

- Excellent part load performance.

- Suitable for a variety of applications, from comfort cooling to process

cooling.

Unsupported file type.