Hot Water Driven Absorption Chillers

Horizontal Fire Tube Boilers

Thermal Oil Heaters

Exhaust Gas Boiler (EGB)

Steam Driven Absorption Chiller

Direct Fired Absorption Chiller

Exhaust Gas Absorption Chiller

Multi Energy Absorption Chiller

Water Cooled Compression Chiller

Air Cooled Compression Chiller

End Suction Pumps

Vertical Multistage Pumps

Borewell Pumps

Water Boosting System

Submersible Pumps

Electromagnetic Flow Meters

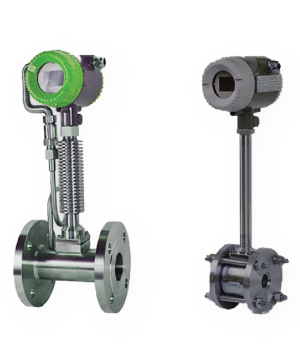

Vortex Flow Meters

Turbine Flow Meters

Mass Flow Meters

Open Channel Flow Meters

Bellows Sealed Valve

Ball Float Trap

Thermodynamic Trap

Garments / Iron Trap

Thermostatic Air Vent

Vacuum Breaker

Sight Glass

Pneumatic Control Valve

Pressure Reducing Valve

Moisture Separator

Strainers

Non Return Valve

Automatic Pump Trap

Condensate Transfer Pumps

Rectangular Cooling Tower

Round Cooling Towers

Gasketed Plate Heat Exchanger

Brazed Plate Heat Exchanger

Water Softener Systems

Reverse Osmosis (RO) Plants

Ultra Filtration (UF) System

Vertical Water Tube Boilers

Coal / Biomass Boiler

Electric Steam Boilers

Diaphragms

Diaphragm Top Assembly

Diaphragms Valves

Vacuum Pumps

Vacuum Pump Kit

Manometer (Absolute Vacuum)

Vacuum Pressure Transmitter

DP (Differential Pressure) Switch

Flow Switch

Vacuum Pump Oil

Octoplus

Corrosion Inhibitor

Lithium Bromide Solution

Ultrasonic Flow Meters

Basic Information

Range: DN 15 ~ DN 6000

Measuring Medium: Water, seawater, acidic liquids, beer, alcohol, oil, and other liquids that can transmit sound.

Medium Temperature: - 30 to 160oC

Accuracy: ± 1%

Output type: One OCT pulse output (pulse width: 6-1000ms, default 200ms).

Power supply: 100 ~ 220V AC

The Ultrasonic Flow Meters is designed to work with clamp-on

transducers to enable the flow of a liquid within a closed pipe to be measured

accurately without needing to insert any mechanical parts through the pipe wall

or protrude into the flow system. Ultrasonic Flow Meters measure the flow by

transmitting ultrasonic sound waves through the fluid. The time-of-flight or Doppler

shift method is used to calculate flow rate based on the difference in the

speed of sound waves moving with or against the flow direction. They are non-intrusive,

offering accurate, reliable measurements without affecting the flow, and are

widely used for liquids and complex fluid systems.

- Offer

accuracy, better than 1%.

- Wide

measurement range from DN15 to DN6000.

- Built-in

high-capacity NiMH rechargeable batteries lasting over 10 hours (fully charged).

- Non-invasive

measurement with clamp-on sensors.

- Built-in data storage, capable of storing up to 2,000 rows of data.

- LCD display shows instant flow, total flow, flow velocity, and working conditions.

Unsupported file type.