Hot Water Driven Absorption Chillers

Horizontal Fire Tube Boilers

Thermal Oil Heaters

Exhaust Gas Boiler (EGB)

Steam Driven Absorption Chiller

Direct Fired Absorption Chiller

Exhaust Gas Absorption Chiller

Multi Energy Absorption Chiller

Water Cooled Compression Chiller

Air Cooled Compression Chiller

End Suction Pumps

Vertical Multistage Pumps

Borewell Pumps

Water Boosting System

Submersible Pumps

Electromagnetic Flow Meters

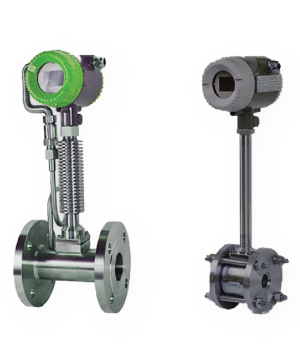

Vortex Flow Meters

Turbine Flow Meters

Open Channel Flow Meters

Ultrasonic Flow Meters

Bellows Sealed Valve

Ball Float Trap

Thermodynamic Trap

Garments / Iron Trap

Thermostatic Air Vent

Vacuum Breaker

Sight Glass

Pneumatic Control Valve

Pressure Reducing Valve

Moisture Separator

Strainers

Non Return Valve

Automatic Pump Trap

Condensate Transfer Pumps

Rectangular Cooling Tower

Round Cooling Towers

Gasketed Plate Heat Exchanger

Brazed Plate Heat Exchanger

Water Softener Systems

Reverse Osmosis (RO) Plants

Ultra Filtration (UF) System

Vertical Water Tube Boilers

Coal / Biomass Boiler

Electric Steam Boilers

Diaphragms

Diaphragm Top Assembly

Diaphragms Valves

Vacuum Pumps

Vacuum Pump Kit

Manometer (Absolute Vacuum)

Vacuum Pressure Transmitter

DP (Differential Pressure) Switch

Flow Switch

Vacuum Pump Oil

Octoplus

Corrosion Inhibitor

Lithium Bromide Solution

Mass Flow Meters

Basic Information

Size: DN15 ~ DN500

Installation

Medium: Various gases

(Except the acetylene)

Medium

Temperature: - 20 to 220oC

Pressure

Rating: 1.6 Mpa

Accuracy: ± 1 % ~

2.5%

Protection

level: IP65

Output type: 4-20mA, RS485 communication, HART protocol

Power supply: 24V DC or 220V AC

The thermal gas mass flow meter operates based on thermal dispersion

and uses the constant differential temperature method to measure gas flow. It

offers advantages such as small size, easy installation, high reliability, and

high accuracy. The meter features two platinum resistance temperature sensors.

The principle works by monitoring the cooling effect of a gas stream as it

flows over a heated sensor. Gas passing through the sensing section flows over

two sensors, one acts as a temperature sensor, while the other functions as a

heater. The temperature sensor tracks the actual process values, while the

heater maintains a constant differential temperature above the process value by

adjusting the power consumed. As the gas velocity increases, so does the

cooling effect, requiring more power to maintain the differential temperature.

The measured heater power, therefore, corresponds to the gas mass flow rate.

- Measures

mass or volume flow of gas.

- No

need for temperature or pressure compensation, offering accurate measurement

and easy operation.

- Wide

range: 0.5 Nm³/s to 100 Nm³/s for gas, also suitable for gas leak detection.

- Excellent

vibration resistance and long service life, with no moving parts or pressure

sensors in the transducer.

- Easy

installation and maintenance, with optional hot-tapped installation (custom

order).

- Digital design for high accuracy and stability.

- Compatible with RS485 or HART interface for factory automation and integration.

Unsupported file type.