Hot Water Driven Absorption Chillers

Horizontal Fire Tube Boilers

Thermal Oil Heaters

Exhaust Gas Boiler (EGB)

Steam Driven Absorption Chiller

Direct Fired Absorption Chiller

Exhaust Gas Absorption Chiller

Multi Energy Absorption Chiller

Water Cooled Compression Chiller

Air Cooled Compression Chiller

End Suction Pumps

Vertical Multistage Pumps

Borewell Pumps

Water Boosting System

Submersible Pumps

Electromagnetic Flow Meters

Vortex Flow Meters

Turbine Flow Meters

Mass Flow Meters

Open Channel Flow Meters

Ultrasonic Flow Meters

Bellows Sealed Valve

Ball Float Trap

Thermodynamic Trap

Garments / Iron Trap

Thermostatic Air Vent

Vacuum Breaker

Sight Glass

Pneumatic Control Valve

Pressure Reducing Valve

Moisture Separator

Strainers

Non Return Valve

Automatic Pump Trap

Condensate Transfer Pumps

Rectangular Cooling Tower

Round Cooling Towers

Brazed Plate Heat Exchanger

Water Softener Systems

Reverse Osmosis (RO) Plants

Ultra Filtration (UF) System

Vertical Water Tube Boilers

Coal / Biomass Boiler

Electric Steam Boilers

Diaphragms

Diaphragm Top Assembly

Diaphragms Valves

Vacuum Pumps

Vacuum Pump Kit

Manometer (Absolute Vacuum)

Vacuum Pressure Transmitter

DP (Differential Pressure) Switch

Flow Switch

Vacuum Pump Oil

Octoplus

Corrosion Inhibitor

Lithium Bromide Solution

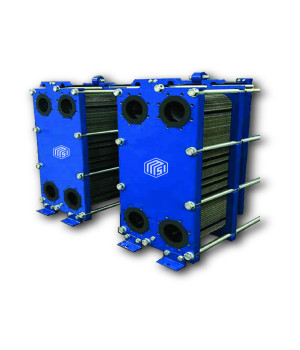

Gasketed Plate Heat Exchanger

Basic Information

Plate

Material: 304/304L,

316/316L, Titanium and others available

Gasket

Material: EPDM, NBR, HNBR, Viton and others

available

Pressure

Plate: Carbon Steel, Stainless Steel and

others available

Connection: Flange, Thread and others

available

Max. Design Pressure: 25 bar

Max. Design Temperature: 170 OC

The Plate Heat Exchanger (PHE) is an advanced solution for efficient

heat transfer. It features a design composed of corrugated metal plates and

precision-engineered gaskets. The gaskets ensure that hot and cold fluids

remain separated within distinct channels, optimizing heat transfer efficiency

while preventing cross-contamination. Ideal application for all types of

industries including power generation, refrigeration, food processing, and

chemical processing.

- Wide variety of materials and designs

- Compact footprint with easy maintenance

- High performance at a lower cost

- Reduced fouling rate for suboptimal media

Unsupported file type.