What Are the Types of Heat Exchangers?

09 Jan, 2025 by

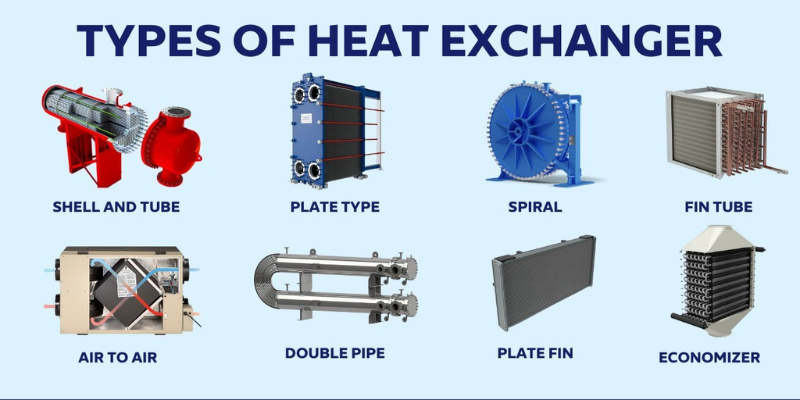

Heat exchangers play a crucial role in transferring heat between two or more fluids, ensuring efficient energy management across industries. From power plants to HVAC systems and chemical processing plants, these devices are indispensable for various applications. But what are the types of heat exchangers, and how do they differ? This guide explores the main types, their working principles, and applications.

1. Shell and Tube Heat Exchanger

The shell and tube heat exchanger is one of the most common types, featuring a series of tubes enclosed within a cylindrical shell. One fluid flows through the tubes while the other flows around them within the shell. Heat transfer occurs through the tube walls.

Advantages:

- High efficiency in heat transfer.

- Suitable for high-pressure applications.

- Modular design for scalability.

Applications:

- Power generation

- Oil refineries

- Chemical processing plants

2. Plate Heat Exchanger

Plate heat exchangers use thin, corrugated plates stacked together to transfer heat. These plates create channels for the fluids, ensuring a large surface area for efficient heat exchange.

Advantages:

- Compact design.

- Easy to clean and maintain.

- Highly efficient for moderate temperature and pressure applications.

Applications:

- Food and beverage industry

- HVAC systems

- Pharmaceutical processes

3. Air Cooled Heat Exchanger

Air-cooled heat exchangers utilize ambient air to cool the working fluid, eliminating the need for water. Fans or natural convection facilitate heat dissipation.

Advantages:

- Water conservation.

- Reduced environmental impact.

- Suitable for remote locations.

Applications:

- Power plants

- Petrochemical plants

- Renewable energy systems

4. Double Pipe Heat Exchanger

This simple design consists of one pipe inside another, with the fluids flowing in opposite directions (counter-flow) or the same direction (parallel flow). The double pipe heat exchanger is ideal for small-scale applications.

Advantages:

- Cost-effective.

- Easy to construct and operate.

- Flexible design.

Applications:

- Refrigeration

- Chemical laboratories

- Small industrial processes

5. Finned Tube Heat Exchanger

Finned tube heat exchangers use extended surfaces (fins) on the tubes to increase the heat transfer area. These are ideal for heat transfer between air and liquids or gases.

Advantages:

- Enhanced heat transfer.

- Suitable for compact spaces.

- Adaptable to various environments.

Applications:

- Automotive radiators

- HVAC systems

- Industrial dryers

6. Regenerative Heat Exchanger

In regenerative heat exchangers, the same fluid transfers heat from the hot side to the cold side. This can be done using a thermal storage medium or by direct heat exchange.

Advantages:

- High thermal efficiency.

- Energy conservation.

- Reduced operating costs.

Applications:

- Gas turbines

- Waste heat recovery systems

- Cryogenic processes

7. Plate and Shell Heat Exchanger

Combining the features of plate and shell and tube designs, this type offers high efficiency and compactness. It is particularly effective in high-pressure and high-temperature applications.

Advantages:

- Compact and robust.

- High thermal performance.

- Versatile design.

Applications:

- Oil and gas industry

- Offshore platforms

- Marine applications

Conclusion

Understanding the types of heat exchangers is essential for selecting the right equipment for specific industrial needs. Whether it’s the robust shell and tube design for high-pressure systems or the compact plate heat exchanger for limited spaces, each type offers unique benefits tailored to various applications. Proper selection and maintenance of heat exchangers not only ensure optimal performance but also enhance energy efficiency and cost savings.